When is raising $14 billion not enough? When you’re a battery startup.

Northvolt, Europe’s attempt at building a competitor to Asia’s battery manufacturing powerhouses, announced on Monday that it had halted work on a factory expansion and laid off 1,600 employees, or about 20% of the workforce.

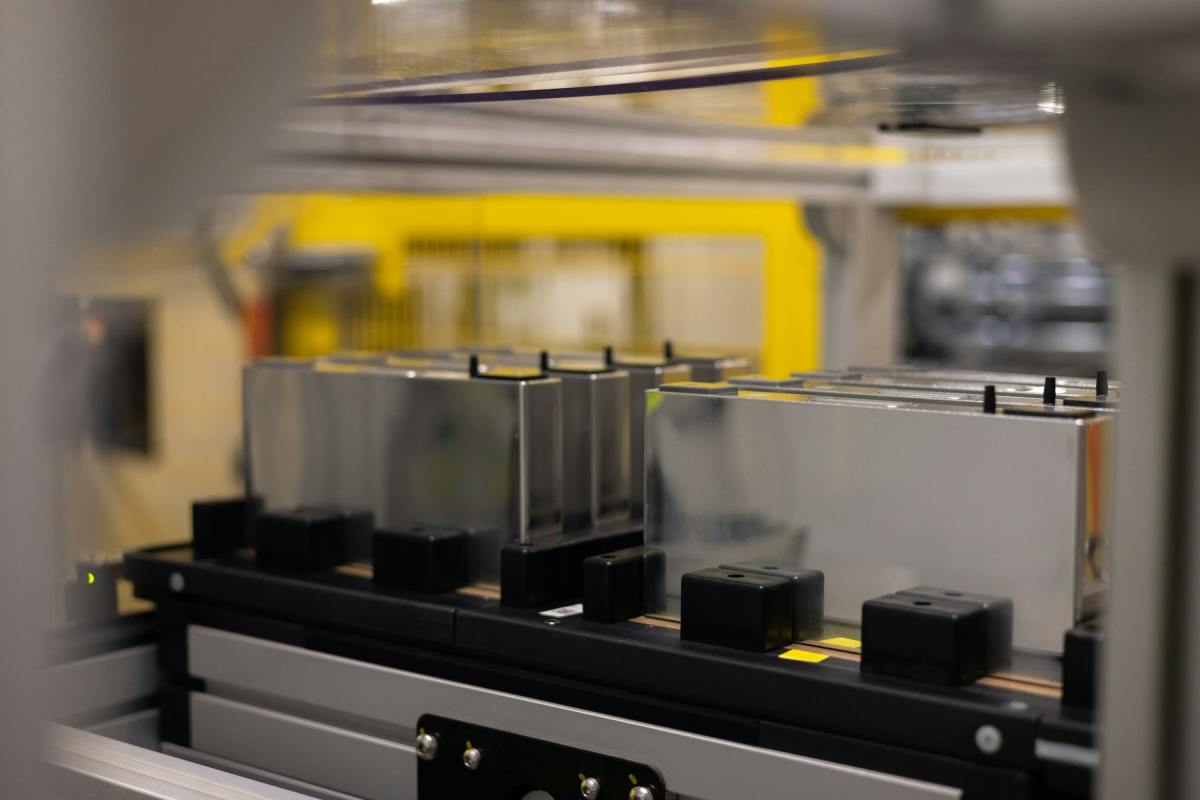

The company was planning to expand its Ett factory in northern Sweden to scale production to 30 gigawatt-hours annually. The expansion would have supplied cathode active material (CAM), a key component required to make completed cells. On September 9, the company also axed another CAM production site in Sweden. Without those factories, Northvolt will almost certainly have to buy it elsewhere, likely from overseas.

The cost cutting is the result of lower-than-expected demand growth, Northvolt said, as automakers trim their forecasts for electric vehicle production. Execution problems are probably also to blame. In June, the company was unable to fulfill an order for BMW on time, leading the German automaker to cancel the €2 billion contract. Northvolt did not immediately reply to TechCrunch’s request for comment, though it’s hard to see how that didn’t influence the company’s cost-cutting measures.

Ultimately, Northvolt faces two challenges.

For one, all battery startups face significant execution risk. Though batteries appear simple from the outside, the chemistry inside is fiendishly complex. It isn’t easy to develop materials that can store energy safely at high densities, that can be recharged at increasingly higher rates, and that can survive for more than a decade inside an automobile. Producing them at a massive scale only compounds the challenge. Just ask GM and LG what happens when you don’t get it right.

Northvolt has additional hurdles to surmount. It’s essentially building a copy of what Asian countries like China and South Korea already possess: a mature, scaled battery-manufacturing sector. Both China and South Korea have been working on it for decades, with consistent government support along the way. By comparison, Northvolt is only eight years old, and it only recently received substantial assistance from the EU and other governments.

The U.S. tried something similar nearly 20 years ago with A123 Systems. The startup pioneered production of lithium-iron-phosphate batteries, which stored less energy than other chemistries but were more durable and safer to charge. It started by selling to power tool manufacturers and then began courting automakers, who even in the late 2000s were projected to buy the sort of volumes that would support large-scale domestic manufacturing.

A123 was in the running to make battery packs for the Chevrolet Volt, but after losing out to LG, its only customer ended up being the first iteration of Fisker, which was also making a plug-in hybrid. After one of those cars caught fire during Consumer Reports’ testing, A123’s fate was all but sealed.

What those high-profile stumbles don’t reveal were the other obstacles A123 faced, most of which revolved around standing up a battery supply chain where there was none. Northvolt has been a bit more successful, in part because there is some political appetite to make it happen. But the Swedish company’s announcements about curtailing CAM production show it’s still not easy to accomplish.

The second challenge that Northvolt faces is that automakers, its key partners, haven’t been able to decide where they stand on EVs. After years spent talking up the transition to all-EV lineups, they’ve since backed off the most aggressive targets. Most automakers’ early forecasts proved overly optimistic, and they appear to have underestimated the amount they’d need to invest to produce successful products. In the face of weaker-than-expected tailwinds, they have plunged into developing hybrids and plug-in hybrids, which require far fewer batteries.

To succeed in early markets requires all players to have conviction. Automakers, parts manufacturers, and investors all need to have bought into an EV future. If any one of them blinks, they all suffer. Northvolt is feeling that pain today.

Does it spell the end of battery manufacturing in Europe or North America, where Northvolt has plans to expand? Hardly. Demand for EVs is still strong and growing. And because batteries are heavy and expensive to ship, it makes sense to produce them near EV factories. Strong incentives courtesy of the Inflation Reduction Act and the European Green Deal help tip the scales further. That doesn’t mean Northvolt can be complacent — it still has to prove it can execute. But by the time that gets sorted, it’s likely the market will be ready for it.